MODA

Project: MODA

MODA

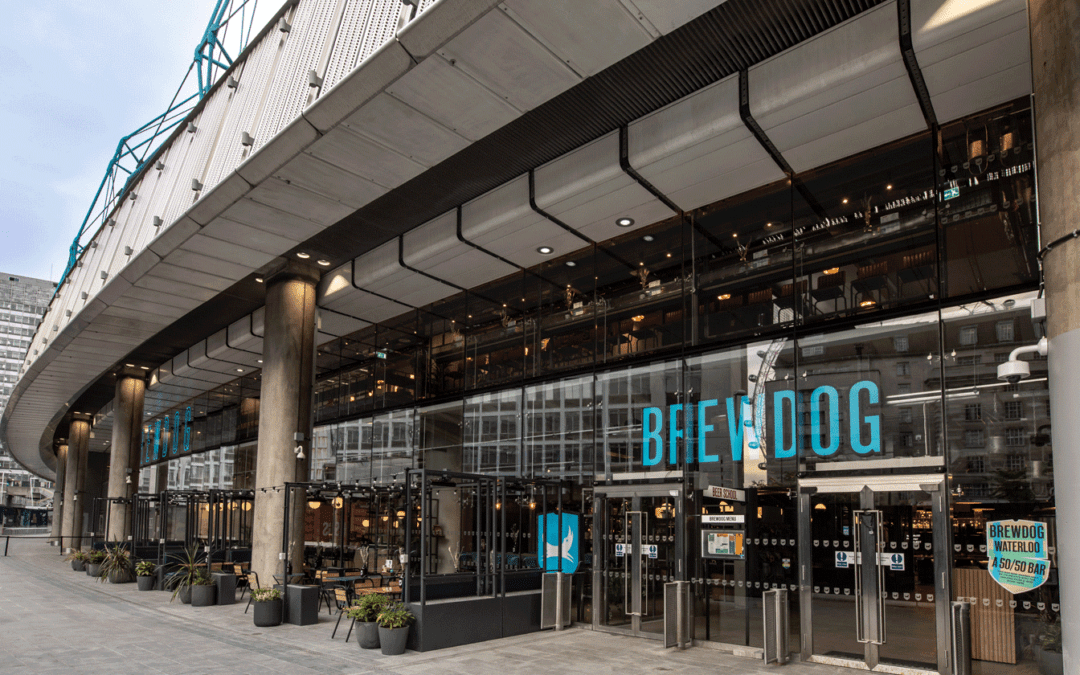

Former Mariner Foods factory floor covering 4400m2. The existing floor was up 270mm out of level.

The client required a new heavy-duty floor suitable for fork lifts and for racking up to 6m in height.

We worked with Murexin to design a warranted specification that consisted of:

- Concrete topping with Sealer

- C40 Speed star screed

- Steel angle movement joints

- New DPM

Project – MODA

Location – London

Product – Supplied by Marshalls Motors & Screed – Murexin Product

Size – (4400m2)

More Projects

CONTACT US

Our Address

Foggs Floors

Unit 1 Mikar Business Park

Northolt Drive

Bolton

BL3 6NJ